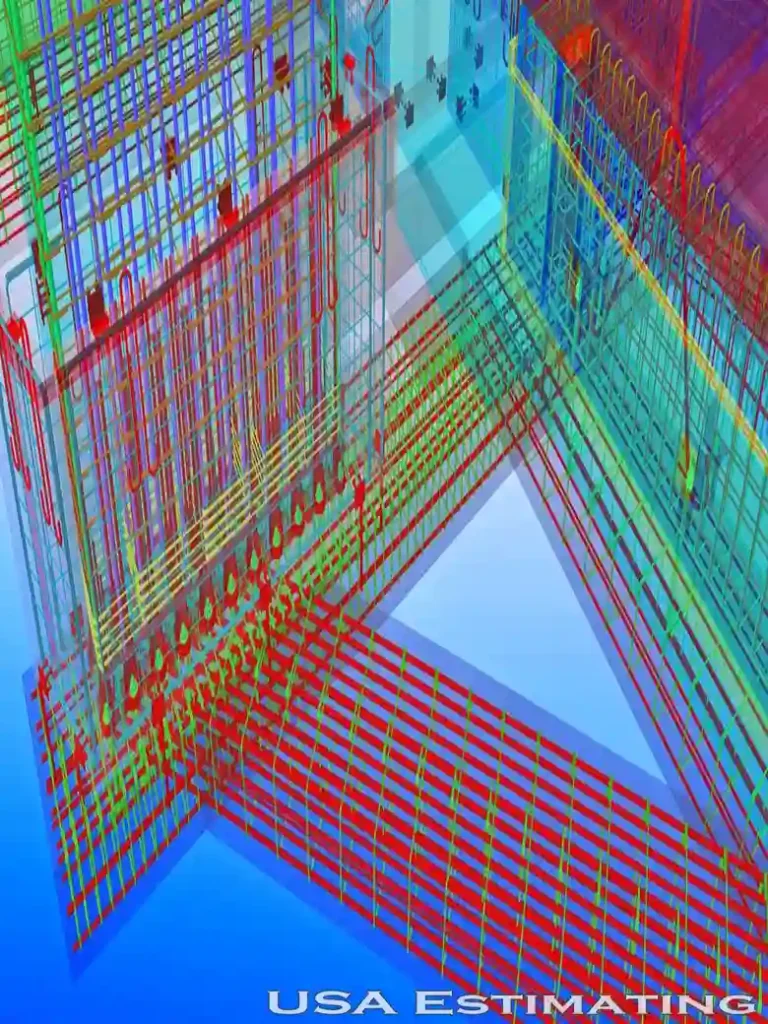

Rebars Cut lengths

Best Construction Estimating Companies in Seattle

Welcome to the hub of construction excellence in Seattle! At USA Estimating Company, we pride ourselves on being among the top construction companies in this vibrant city. Specializing in Rebar Cutlengths Services, we offer tailored solutions that optimize material usage and ensure cost-effectiveness for your construction projects.

Our commitment to quality and precision sets us apart. Whether you’re working on large-scale commercial developments or intricate residential projects, our expertise in providing customized rebar lengths will streamline your construction process. We understand the importance of meeting unique project requirements, which is why we offer specialty rebar sizes and detailed BOQs (Bill of Quantities) tailored to your specifications.

At USA Estimating Company, we specialize in providing comprehensive rebar cut and bent services tailored to meet your construction needs. Our Rebar Cutlengths Services are designed to optimize rebar usage, ensuring every cut length is efficiently utilized without waste. Drawing from our extensive experience, we craft bar bending schedules that minimize material wastage while adhering to project specifications, thereby optimizing costs and sustainability.

Seeking specialty rebar sizes like #10 / 1.25" for artistic or industrial applications? Look no further. Our services offer tailored lengths, eliminating the need to purchase excessive quantities. We facilitate trades and sourcing to ensure you get precisely what you need, saving you time, effort, and unnecessary expenses.

We understand the frustration of acquiring non-standard rebar sizes. Our network and expertise enable us to assist you in obtaining larger diameters like #10 or substantial sizes such as #14 efficiently and promptly. Contact us today to discuss your unique project needs.

Our Rebar Cutlengths Services provide detailed BOQs (Bill of Quantities) in customer-specific formats, ensuring clarity and transparency in procurement and construction planning. We prioritize quality assurance and compliance, assuring you that our reinforcing steel is quality assured and compliant with standards like BS 8666.

Logistics and delivery play a significant role in project timelines. We offer express delivery options and accommodate urgent orders, ensuring your project stays on schedule without compromising quality.

Concerned about the implications of cutting rebar on structural integrity? Our experienced team ensures meticulous planning and execution to minimize risks associated with altering reinforced concrete. We also offer protective measures against moisture and rust, safeguarding rebar and enhancing durability.

Whether you're tackling a large-scale project or need customized pieces, our Rebar Cutlengths Services are tailored to address challenges like material optimization, precise quantities, and sourcing specialty rebar sizes. Let USA Estimating Company be your partner in reinforcing your construction endeavors with precision and expertise. Contact us today at 01942 322210 to discuss how we can assist you.

FAQ

Accurately estimating rebar for concrete projects is crucial for ensuring structural integrity and project success. Drawing from my extensive experience as a construction estimator, I am offering a comprehensive guide to help you navigate the rebar estimation process effectively.

Comprehensive Guide to Estimating Rebar in Concrete:

To estimate rebar in concrete, several factors and methodologies come into play, each contributing to a thorough and accurate estimation process. Here’s a breakdown of the essential steps and considerations:

- Begin by understanding the specific requirements of your construction project, including structural design codes, anticipated loads, and type of structure.

- Obtain and review structural drawings provided by engineers or architects to gather essential information about dimensions, reinforcement spacing, and bar sizes.

- Measure and calculate the total length of reinforcement bars needed for the concrete elements, ensuring precise calculations for each component.

Factor in any required overlaps for reinforcement continuity and bends necessary for structural integrity, ensuring proper placement throughout the concrete structure.

- Based on design requirements and load considerations, determine the appropriate spacing and diameter of the reinforcement bars while adhering to local building codes and standards.

- Utilize formulas or online resources to determine the weight of each rebar based on its diameter and length, then multiply by the total length to ascertain the overall weight required for the project.

- Account for potential wastage or additional reinforcement needed due to construction tolerances or specific design considerations, allocating a percentage of the total rebar weight as an allowance for these factors.

- Seek guidance from qualified structural engineers or industry professionals to ensure accuracy in rebar estimation tailored to your project's requirements, especially when uncertainty arises.

- Material and Labor Costs: Factor in the costs associated with rebar procurement and installation labor, considering fluctuations in material prices and local labor rates.

- Environmental Conditions: Account for environmental factors such as temperature, humidity, and exposure to elements, which can affect the concrete curing process and overall project timeline.

- Inspection and Testing: Implement regular inspection and testing protocols throughout the construction process to verify the quality of concrete and reinforcement installation.

- Documentation and Record-Keeping: Maintain detailed documentation of rebar quantities, installation procedures, and testing results for future reference and compliance purposes.

To calculate the quantity of rebars needed for the length, divide the length of the pour by the selected spacing. Similarly, for the width, divide the width of the pour by the spacing. Then, multiply the results of these divisions to determine the total number of rebars required for the grid.

Conclusion:

By following these steps and considering additional factors while integrating quality assurance measures into the estimation process, you can enhance the reliability and success of rebar estimation in concrete construction projects. With meticulous planning, attention to detail, and collaboration with experts, accurate estimation becomes achievable, ensuring the strength, durability, and longevity of your concrete structures.

Estimate Rebar Weight:

Use the formula Weight (lbs)=Diameter (in)2×Length (ft)×0.668Weight (lbs)=Diameter (in)2×Length (ft)×0.668 to estimate the weight of rebar needed for each element. This formula assumes the rebar is made of standard carbon steel.

Estimating Concrete Cutting: A Comprehensive Guide

With over 15 years of experience as a construction estimator and project manager, I understand the critical importance of accurate concrete cutting estimates for successful project execution. Whether it’s for creating openings, removing sections, or modifying concrete structures, precise estimation is crucial for effective budgeting and planning. Drawing on extensive experience in the field, this guide provides detailed and reliable information. Professionals such as construction managers, cost estimators, and project engineers will find this advice trustworthy and valuable for ensuring successful concrete cutting projects.

Here’s a comprehensive guide on how to estimate concrete cutting effectively.

- Begin by thoroughly examining the area where concrete cutting is required. Note the size of the area, depth of cuts, and any specific requirements such as angles or patterns.

- Measure the length and width of the area to be cut to determine the square footage. For irregular shapes, break down the area into smaller sections and calculate each section's square footage separately.

- Decide on the depth of the cuts required based on project specifications and what lies beneath the concrete surface.

- Different cutting methods have varying costs. Determine the most suitable method based on precision needed, access limitations, and budget.

- Contact reputable concrete cutting companies and provide detailed information about the area to be cut. Request quotes considering dimensions, depth, and any special requirements.

- Review quotes from different companies, considering costs, experience, equipment quality, and customer reviews.

- Account for cleanup, waste disposal, and potential repairs to surrounding structures or utilities.

- Discuss the estimated time frame with concrete cutting companies and factor in any deadlines or time constraints.

- Ensure all project details are clearly outlined in a written contract before work begins.

- Stay in communication with the concrete cutting team throughout the project to address any concerns or issues.

Conclusion:

Accurately estimating concrete cutting requires thorough assessment of the project scope, consideration of various factors such as size, depth, cutting method, and additional costs, as well as obtaining quotes from reputable contractors. By following these steps and being diligent in the estimation process, you can ensure successful concrete cutting projects that align with your requirements and budget constraints.